معمولا یکی از مشکلاتی که در رنگرزی دیسپرس پیش می آید انتخاب یکنواخت کننده بی کیفیت است .

در اینجا عوامل انتخاب یکنواخت کننده مناسب بیان شده است :

1 – سرعت رنگرزی: سرعت پایین جذب رنگ در مراحل اولیه رنگرزی اولین فاکتور انتخاب یکنواخت کننده می باشد.

2 – مهاجرت رنگ: افزایش مناسب میزان مهاجرت رنگ در حضور یکنواخت کننده نسبت به عدم حضور یکنواخت کننده.

3 – اکروماتیک پایین: ضمن بالا بودن میزان مهاجرت و پایین بودن سرعت جذب کمترین میزان کاهش قدرت رنگ فاکتوری مهم در این انتخاب میباشد.

4 – دیسپرس کنندگی بالا: کاهش تجمع رنگ (کلوخه نشدن رنگ) در آب در حضور یکنواخت کننده نسبت به عدم حضور یکنواخت کننده آخرین فاکتور انتخاب میباشد.

How can test levelling agent of polyester disperse dyeing:

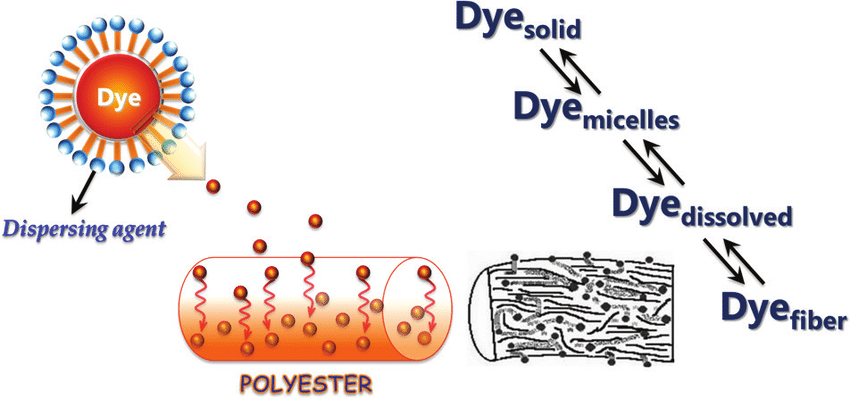

Disperse dyes are non-ionic dyes with low water solubility. Generally, high temperature and high pressure are used for dyeing. In order to achieve uniform dispersion and dyeing, leveling agents are generally used in the dyeing process. Today, Baike will talk to you about the choice of disperse dye leveling agents.

Slow dyeing

The slow dyeing property of the levelling agent can inhibit the instantaneous dyeing in the initial stage of dyeing, which is the primary factor in choosing the levelling agent. The test method for slow staining is generally as follows:

Experimental materials

Sample: polyester fabric after degreasing and refining

formula:

C.I. Disperse Orange 30# 0.5% (O.M.F)

C.I. Disperse Red 60# 0.5% (O.M.F)

C.I. Disperse Blue 79# 0.5% (O.M.F)

Levelling agent x g/L

pH: 4.5

Bath ratio: 1:20

Experimental technology

Stock solution dyeing: dyeing at 40℃, 30min heating up to 130℃, dyeing for 45min, sampling 6 times at 90℃, 100℃, 110℃, 120℃, 130℃, 130℃×45min, half of the cloth sample taken out is reduced and washed (Sodium hydroxide 2g/L, NaOH 2g/L, 80℃×20min), the other half is rinsed with tap water for about 30s and dehydrated and dried.

Residue dyeing: After each sampling, measure 40mL of dyeing residue and add 2g polyester cloth for dyeing. The process is the same as above.

Result evaluation

The more even the color gain between the dyed samples at each sampling point, the lighter the relative color, indicating that the levelling agent has a better retarding effect.

Migration

Dye migration is the process in which the levelling agent re-disperses the high dye concentration part of the dyed fabric into the dye bath, and then dyes the low dye concentration part. Dye migration is an important performance of the disperse dye repair agent.

Regarding migration, the following methods are generally used for testing:

Experimental materials

Dyed polyester fabric: red (Un-se Red 0.5%) + yellow (Un-se Yellow 0.8%) + blue (Un-se Blue 0.5%) + undyed polyester fabric each, four fabric sheets The edges are stitched together to form a set.

formula:

Levelling agent x g/L

pH 4.5-5

Bath ratio 1:20

Experimental technology

Dyeing at 40°C, 30min heating up to 130°C and transferring dyeing for 60min, take out the cloth sample, wash with water, and dry.

Result evaluation

The closer the color of each color sample in the combination after migration, the better the migration effect.

Achromaticity

For disperse dye levelling agents or color repairing agents, while achieving good retardation and migration effects, the smaller the decolorization, the better the performance of the auxiliary. The test method of decolorization is recommended as follows:

Experimental materials

Sample: 4g polyester knitted fabric after degreasing

formula:

Levelling agent x g/L

C.I. Disperse Blue 79# 0.05% (O.M.F)

pH: 4.5

Bath ratio: 1:20

Experimental technology

Dyeing at 40°C, heating to 130°C for 30min, dyeing for 60min, take out the cloth swatch, wash with water, and dry.

Result evaluation

Take the blank (no levelling agent) dyed fabric sample strength as the standard sample to determine the color strength and color difference DE (also visually detectable) of the dyed fabric sample under different leveling agents (color correction agents) and dosage conditions, the higher the strength , The smaller the chromatic aberration, the less achromatic.

Dispersion

Dispersibility is also one of the necessary conditions for a good leveling agent for disperse dyes. The dispersibility of the leveling agent can avoid the agglomeration of the dye during the dyeing process (generally, a dispersant is added in the production process of disperse dyes). The following is the leveling agent dispersion A test method of sex:

Experimental materials

formula:

C.I. Disperse Red 167# 1.0g/L

Levelling agent x g/L

pH 4.5

Total liquid volume 100mL

Experimental method

Dye liquor heat treatment: heat the dye liquor to 130°C for 30 minutes, and then lower the temperature to 70°C at a rate of 2°C/min.

Dye liquor filtration: first preheat the Buchner funnel with 70℃ hot water and dry it with a towel, then stack the medium-speed qualitative filter paper on top of the fast qualitative filter paper, put it in the funnel, turn on the vacuum pump, and transfer the dye liquor at 70℃ Pour into the funnel. When the appearance of the filter paper changes from wet to dry, it is the endpoint. Take out the filter paper and dry the upper layer of filter paper for evaluation.

Result evaluation

Visually inspect the dye precipitation on the filter paper, the less the dye color point, the better the dispersion.